Dangers of Sodium Cyanide: Understanding the Overall Industry

Chemical Properties of Sodium Cyanide

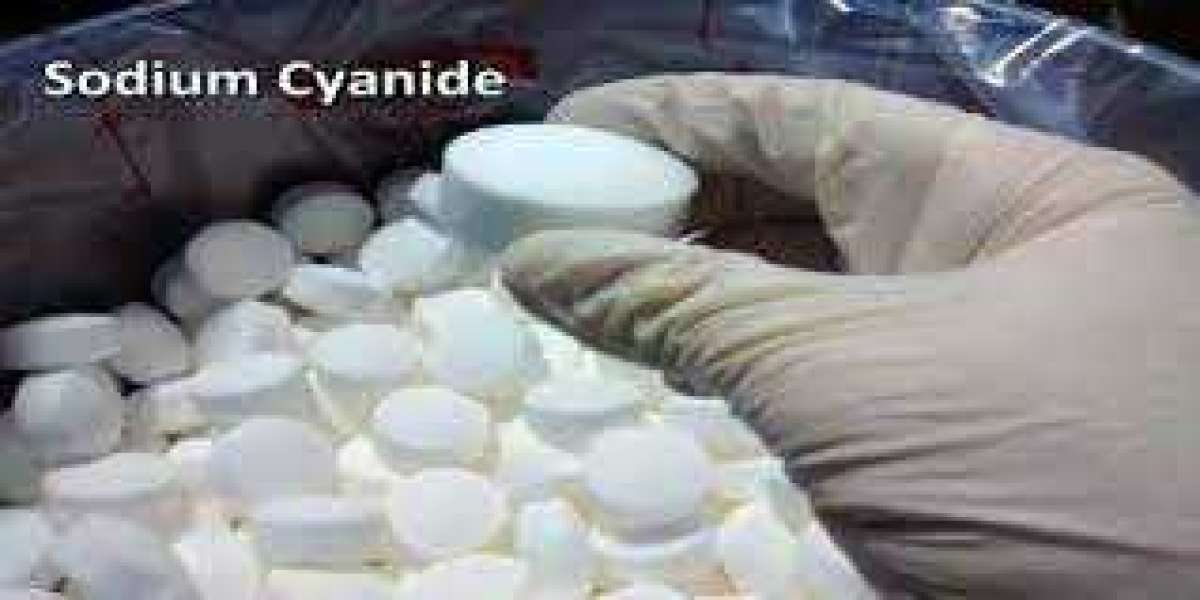

Sodium cyanide (NaCN) is an inorganic compound belonging to the family of cyanides. It is a white, crystalline solid that exhibits high solubility in water. When dissolved in water, it dissociates into sodium and cyanide ions. Cyanide ions are highly reactive and readily bond with various metals. This chemical reactivity forms the basis of many industrial applications of NaCN. At room temperature, NaCN exists as cubic crystals or as a white crystalline powder. It has a low melting point of 558°C and decomposes above that temperature, releasing toxic hydrogen cyanide gas.

Production and Uses of Sodium Cyanide

Sodium cyanide is commercially produced by reacting ammonia and hydrogen cyanide under pressure in the presence of sodium metal. The reaction yields NaCN crystals along with ammonium cyanide as a byproduct. Major applications of NaCN include gold mining, metal plating, and production of certain dyes and pigments. In mining operations, it forms complexes with gold that can be recovered from the ore through extraction processes like cyanidation. This property enables effective and economical extraction of gold from low-grade ore bodies. NaCN is also used extensively in electroplating of metals like copper, silver, zinc, and brass onto various substrates. It acts as a catalyst in many reactions meant for producing pigments and dyes.

Toxic Effects of Sodium Cyanide

Despite its widespread industrial uses, NaCN is highly toxic to humans and requires careful handling. Its toxicity stems from the release of cyanide ions that interfere with cellular respiration in humans. Cyanide ions strongly bind to ferric iron in cytochrome c oxidase, the final electron transport protein in the mitochondrial electron transport chain. This binding effectively inhibits cellular respiration by blocking the transfer of electrons from cytochrome c to oxygen. As a result, the cells cannot generate enough adenosine triphosphate (ATP) required for essential metabolic processes.

Some key toxic effects observed due to sodium cyanide exposure or poisoning include:

- Dizziness, headache, weakness, and confusion due to reduced oxygen supply to the brain.

- Rapid breathing, tremors, and cardiovascular collapse due to tissue hypoxia.

- Seizures, loss of consciousness, and coma progressing to death if not treated promptly.

- Exposure through ingestion or inhalation has immediate effects while skin contact may lead to delayed onset of symptoms.

The lethal dose of sodium cyanide for an adult human is reported to be 200-300 mg. However, as little as 1-5 grams can prove fatal depending on the rate of absorption and individual factors. Inhalation of hydrogen cyanide gas is particularly dangerous as it allows for rapid absorption through lungs. Even sub-lethal doses may cause serious injuries to the central nervous system and heart with long-lasting effects.

Regulation and Safe Handling of Sodium Cyanide

Considering its high acute toxicity, NaCN is designated under Schedule 1 of the Chemical Weapons Convention and regulated as a toxic industrial chemical in many countries. At industrial facilities where NaCN is handled or stored, strict safety precautions and control measures are mandated to minimize risks of exposure. Workers directly involved in its production, transportation, or processing require specialized training regarding emergency response procedures in case of accidental releases.

Some key recommendations for safe sodium cyanide handling include:

- Proper use of personal protective equipment like gloves, eye-goggles, and respirators as applicable.

- Maintenance of adequate ventilation in work areas and storage facilities.

- Segregation from incompatible materials to avoid risk of fires or explosions.

- Decontamination of any spills using appropriate absorbents or neutralization procedures.

- Secure storage in ventilated, dry rooms with spill containment systems and warning signs.

- Regular industrial hygiene monitoring to ensure worker exposure remains within permissible limits.

- Ready access to emergency response equipment like safety showers, eye wash stations and cyanide antidotes.

Adherence to strict safety protocols helps curb both acute and chronic risks to human health during industrial production, transportation, use and waste management of this hazardous chemical. Long term trends also indicate growing preference for safer substitutes wherever technically and commercially viable.

Search

Popular Posts

-

The mobile app Pin Up casino

The mobile app Pin Up casino

-

Laser Cleaning Dry Market Size, Industry & Landscape Outlook, Revenue Growth Analysis to 2030

Laser Cleaning Dry Market Size, Industry & Landscape Outlook, Revenue Growth Analysis to 2030

-

Shop the Latest Collection of Fans at Malta's Leading Store - Fans Malta

Shop the Latest Collection of Fans at Malta's Leading Store - Fans Malta

-

Looking for a new high efficient product for your home or office?

Looking for a new high efficient product for your home or office?

-

Looking for a new high efficient product for your home or office?

Looking for a new high efficient product for your home or office?