Advancements in Medical Device Coatings

Medical device coatings have come a long way in recent decades. Early devices were often uncoated or had very basic coatings designed primarily for corrosion resistance. As the medical industry focused more on biocompatibility and specific clinical needs, coatings evolved to serve new purposes. Some key developments that expanded the capabilities of medical coatings include:

- Increased Control of Surface Properties: Improved deposition techniques allow for tighter control of Medical Coatings thickness, uniformity, composition and surface chemistry. This enabled properties like wettability, lubricity and resistance to cellular/protein adhesion to be finely tuned.

- Drug-Eluting Capabilities: Coatings are now used to controllably release pharmaceutical and genetic agents from implants, helping to prevent issues like restenosis. This drug-eluting function has driven major innovations for stents and joint replacements.

- Infection Resistance: Antimicrobial coatings hold promise for reducing device-related infections. Silver, antibiotics and other agents can be built into coatings to combat bacteria. Some coatings even show activity against biofilm-forming microbes.

- Biocompatibility Enhancement: Coatings provide robust barriers protecting patients from potentially hazardous base materials of devices. They also improve tissue integration for implants through optimized surface energetics and functional groups.

Functionality of Medical Coatings

Today’s medical coatings fulfill diverse roles dictated by the device and intended usage. Some key functional categories include:

- Barrier Coatings: Used extensively on implants, these coatings provide isolation of patients from base materials like metals that could corrode or leach ions. They ensure long-term biocompatibility.

- Drug Elution Coatings: As noted, these coatings controllably release pharmaceutical agents from medical devices. They are widely applied to stents, sutures, meshes and joint replacements.

- Antimicrobial Coatings: Critical for reducing infections, these coatings inhibit or kill microbes using agents like silver, antibiotics, quaternary ammonium compounds and others.

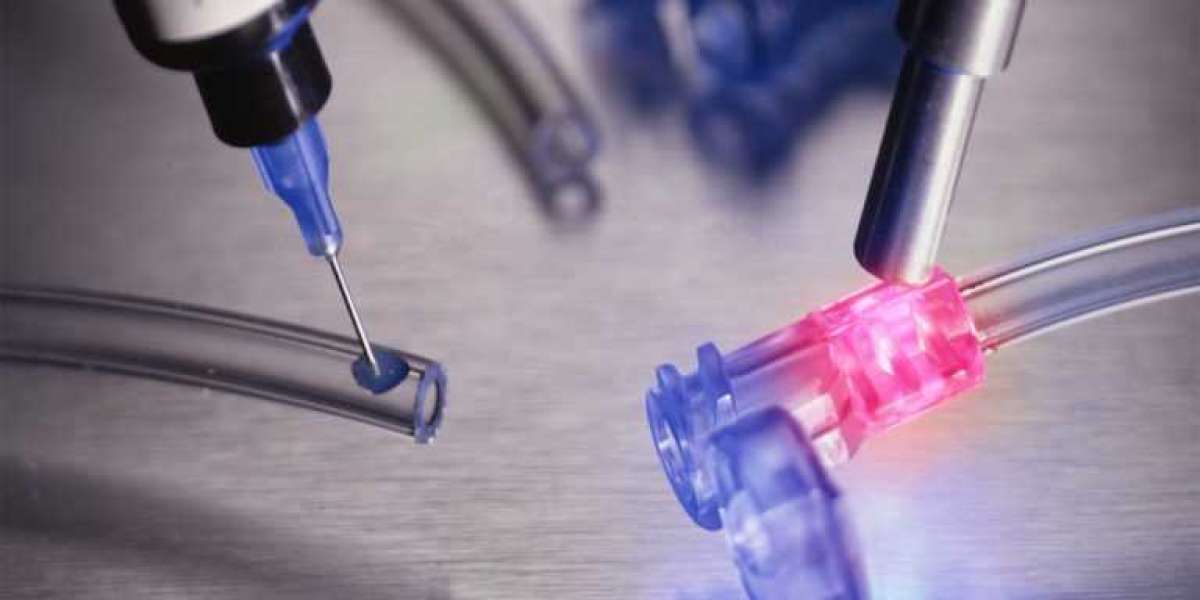

- Lubricious Coatings: Applied to devices that contact tissues or move within the body, these coatings reduce friction and protect against wear. Examples include coatings for implants, catheter shafts and endoscopes.

- Optical Coatings: Used on endoscopes, laparoscopes and other medical cameras, optical coatings ensure clear imaging, anti-fogging and anti-reflective functionality.

- Electrical Coatings: Applied to devices with electrical components like pacemakers and neural stimulators, these coatings provide insulation and corrosion protection.

Get More Insights on- Medical Coatings

For Deeper Insights, Find the Report in the Language that You want:

About Author:

Money Singh is a seasoned content writer with over four years of experience in the market research sector. Her expertise spans various industries, including food and beverages, biotechnology, chemical and materials, defense and aerospace, consumer goods, etc. (https://www.linkedin.com/in/money-singh-590844163)