In this article we will explain how dehydrated food is produced and the ways in which it can be used. Not only can dehydrated food be stored for longer but when processed properly it can add a wonderful boost to any variety of foods and add a new dimension to your cooking everyday.

To turn fresh fruit into a dehydrated product is extremely interesting and below we will show you how it is done with apples.

1. The fresh ripe apples are first hand sorted (it's important that the apples to be dehydrated are at the right stage of ripeness). The apples must be firm enough to be peeled without them crumbling.

2. The apples are then thoroughly washed and rinsed and from washing they go directly to the automatic peeler and coring machines.

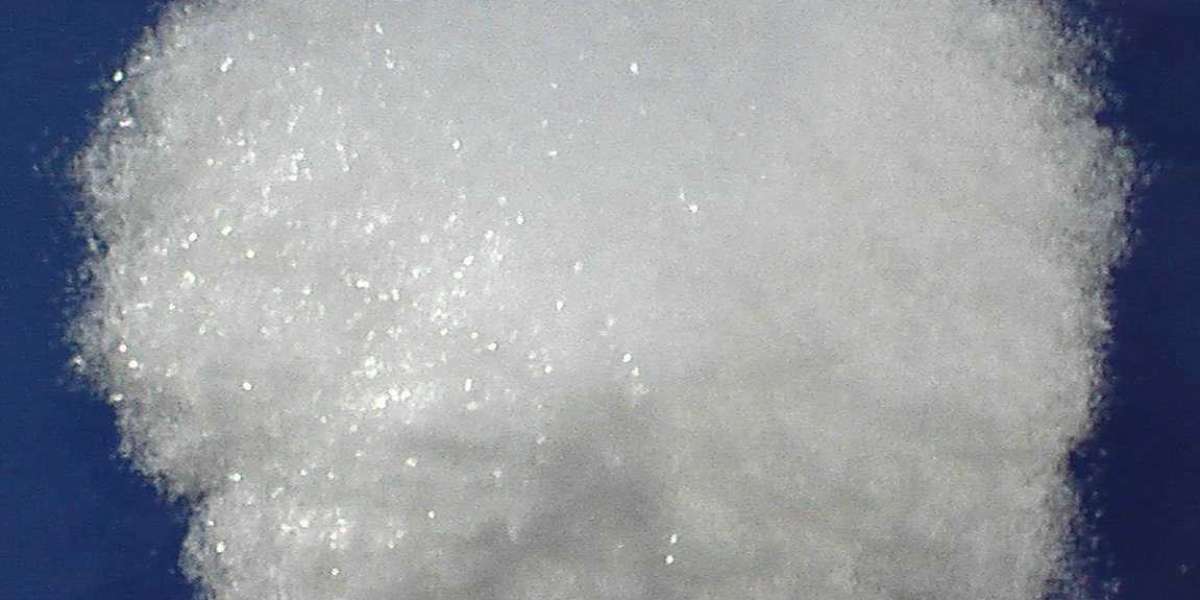

3. Now they apples are cut into different sizes either as apple flakes or slices.

4. Next the apple pieces are coated with 900 to 1,500 ppm (parts per million) of sulfur dioxide or sodium sulfite (which are anti browning agents).

5. Then they are placed in the fruit dryers. The first drier is 350 feet long (and is gas fired). The apples take 45 minutes to pass through this drier (which is at a temperature of 158 Degrees Fahrenheit (70 Degrees Centigrade).

6. Once they have passed through this drier the moisture content of the apple pieces has dropped to 24% and then they pass through a further drier where the moisture levels are further reduced to 3%.

7. To finish off the process strawberry or peach juices along with other flavourings are added to the apple pieces.

Because these fruit pieces are processed at relatively low temperatures the nutrients to be found in any type of fruit remains relatively intact because of this process.

As you can see the processes for producing dehydrated fruit not just apples is quite simple and by using this method will help to reduce the cost of shipping such products and thus makes a saving to the customer.

However if you wish to re-hydrate any fruit pieces it is just a simple case of soaking them in a large amount of water to reverse the process.